-

What Is The MOQ?

RUNZE: MOQ depends on different items.

1 -

How Do I Order Your Products?

RUNZE: You can check our website for any items you interest in, and you can also get communication with our export sales and order for it accordingly.

2 -

What makes you different from others?

RUNZE: a.Our Excellent Service We promise to reply with a price within 24 hours - sometimes even within the hour.

b.Our quick manufacturing time For Normal orders, we will promise to produce within 5-35days.

As a factory, we can ensure the delivery time according to the formal contract.3 -

Is OEM or ODM service available?

RUNZE: Yes, we can provide OEM or ODM service to you and can put your logo on the goods.

4

Custom Die Casting Fabrication Services for Automotive Components

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

Die casting fabrication is a high-precision manufacturing process used to produce complex metal parts with exceptional accuracy and surface quality. By forcing molten metal into a steel mold under high pressure, this process enables the production of intricate designs that are lightweight, durable, and cost-effective. Die casting is widely used in industries such as automotive, aerospace, electronics, and consumer goods to create high-performance components. Our die casting fabrication service offers custom solutions for both small and large-scale production, ensuring fast turnaround times and high-quality results.

Our die casting fabrication service provides top-tier solutions for creating durable, complex, and precise metal parts. Using advanced die casting machines and high-quality molds, we can produce parts with intricate shapes, fine details, and smooth finishes. Our process ensures minimal material waste and high production efficiency, making it ideal for both prototyping and high-volume manufacturing.

- High Precision: We use advanced die casting techniques to produce parts with tight tolerances and high dimensional accuracy.

- Material Flexibility: We offer a wide range of materials, including aluminum, zinc, and magnesium alloys, to meet the specific needs of various industries.

- Cost-Effective Production: Die casting is a highly efficient process, reducing production costs and minimizing waste, making it ideal for large-scale manufacturing.

- Durability and Strength: The die casting process creates metal parts that are robust, lightweight, and resistant to wear, corrosion, and heat, ensuring long-lasting performance.

- Complex Shapes: Die casting allows for the production of intricate designs and complex geometries that would be difficult or impossible to achieve with other manufacturing methods.

- Customization: We provide tailored die casting solutions, from mold design to final part finishing, ensuring that each component meets your exact specifications.

Whether you're looking to produce automotive parts, electronic enclosures, or other high-precision components, our die casting fabrication service ensures top-quality products delivered on time and within budget.

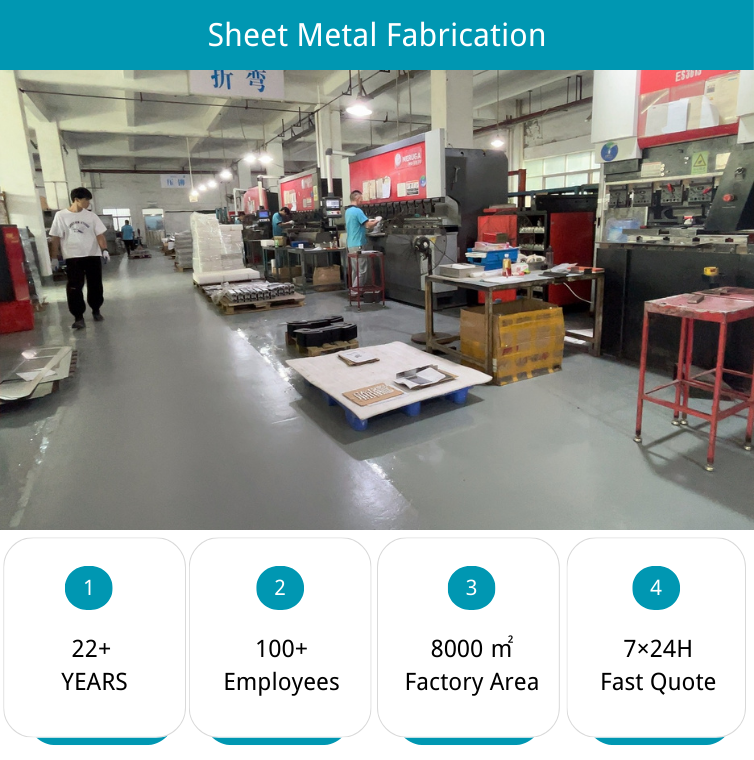

.png)

Shenzhen Runze Metal Technology Co., Ltd, is a professional OEM & ODM metal fabrication manufacturer since 2003. The main products include sheet metal parts, stamping parts, CNC machining parts, aluminum profiles, custom metal tubes, molds, and die castings. In addition, Runze can provide design assistance, assembly, testing,g, and end-to-end management to customers with comprehensive solutions.

The factory has advanced production capabilities and strong technical expertise. We obtained ISO 9001:2015 quality management system certification and have been certified by third parties, including BV, TUV, SGS, CTI. Runze is committed to becoming a global influential custom metal fabrication enterprise.

Over the past years, Runze has established long-term partnerships with more than 300 customers in more than 45 countries. The projects cover various fields, including government projects in Spain, industry-leading enterprise from Germany, Unmanned smart supermarket shelves for Walmart and LED industrial lighting projects from the United States, AI-powered autonomous metal frame, custom liquid cooling metal enclosures and so on. Meanwhile, the supplier of metal housings to leading global companies in the telecommunications industry since 2003.

Warmly welcome you to provide PDF, CAD or STEP drawings, design concepts, prototypes, or samples, and we are dedicated to providing professional quotations and technical support. We sincerely invite friends from all over the world to visit Runze, explore cooperation opportunities, and work together for mutual benefit. Welcome to offer a trial order with your drawings!

.png)

.png)

Q1: What materials are commonly used in die-casting fabrication?

A1: The most common materials used in die casting are aluminum, zinc, and magnesium alloys, as they offer excellent strength, lightweight properties, and corrosion resistance.

Q2: What are the advantages of die-casting fabrication?

A2: Die casting provides high precision, complex shapes, smooth surface finishes, and excellent durability. It is also cost-effective for mass production and minimizes material waste.

Q3: What industries use die-casting fabrication?

A3: Die casting is widely used in the automotive, aerospace, electronics, telecommunications, medical, and consumer goods industries for producing high-quality metal parts.

Q4: What is the difference between die casting and other metal fabrication processes?

A4: Die casting is a high-pressure metal casting process that allows for complex shapes and high accuracy, while other methods, such as CNC machining or sheet metal fabrication, may be better suited for simpler or low-volume production.

Q5: What surface finishes can be applied to die-cast parts?

A5: Common finishes include anodizing, powder coating, electroplating, painting, and polishing, depending on the functional and aesthetic requirements of the final product.

Q6: Can die casting be used for small batch production?

A6: While die casting is most cost-effective for large-scale production, it can also be used for small batches with proper mold design and optimization.

Q7: What are the tolerances achievable in die-casting fabrication?

A7: Die casting can achieve very tight tolerances, often within ±0.1mm, depending on the material and part design.

Q8: How long does it take to produce a custom die-cast part?

A8: Lead times vary based on design complexity and order quantity. Generally, prototype development takes 2-4 weeks, while mass production can be completed within a few weeks after mold creation.

Q9: What factors influence the cost of die-casting fabrication?

A9: Costs depend on material choice, mold complexity, production volume, surface treatment, and additional machining requirements.

Q10: Can die-cast parts be further machined after casting?

A10: Yes, secondary machining processes like CNC milling, drilling, and tapping can be applied to achieve finer details and precise dimensions if needed.

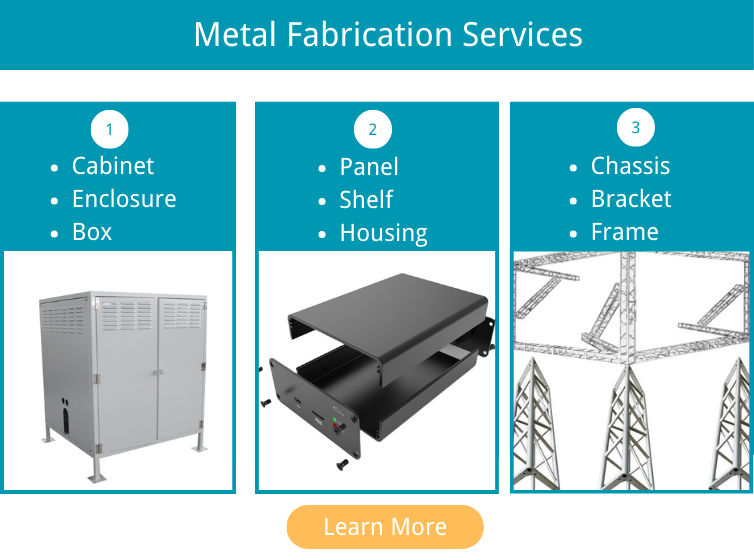

Our major products: Sheet metal cabinet, housing, chassis, electronic appliance housing, medical device housing, communication and electric distribution box, system control cabinet, Stainless Steel and metal hardware accessories, multimedia advertisement cabinet, self-service terminal, electric charging station housing.

Any of your ideas, designs of electric junction metal box, we will make it.

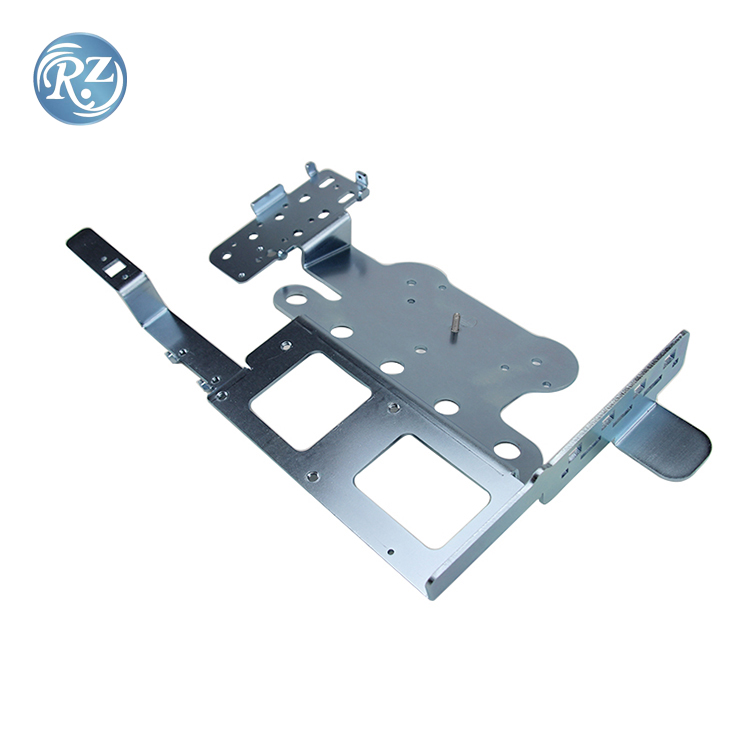

Sheet metal galvanized bracket

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

CONTACT US

Singoo insists on an international team, localized service, insists on the introduction of excellent foreign employees, and enhances the company's professional capabilities

- Address :

4th Floor, Building 8, Huayi Innovation Park, Lane 912, Bibo Road, Pudong New Area, Shanghai

- Phone : +86 15889311698

- Email : melissazhang@runzehardware.cn

- Whatsapp : +86 15889311698

.jpg?x-oss-process=image/resize)

.jpg?x-oss-process=image/resize)

.jpg?x-oss-process=image/resize)

.jpg?x-oss-process=image/resize)

.jpg?x-oss-process=image/resize)

.jpg?x-oss-process=image/resize)

.jpg)

.jpg?x-oss-process=image/resize)

.jpg?x-oss-process=image/resize)

.jpg?x-oss-process=image/resize)

.jpg?x-oss-process=image/resize)

.jpg?x-oss-process=image/resize)

.jpg)